Source High-Quality Reclaimed Glulam Beams: Top Suppliers and Tips

Reclaimed Glulam beams (Glue-Laminated Timber) are available through diverse channels like unalam.com for online purchases, local lumber yards, and co…….

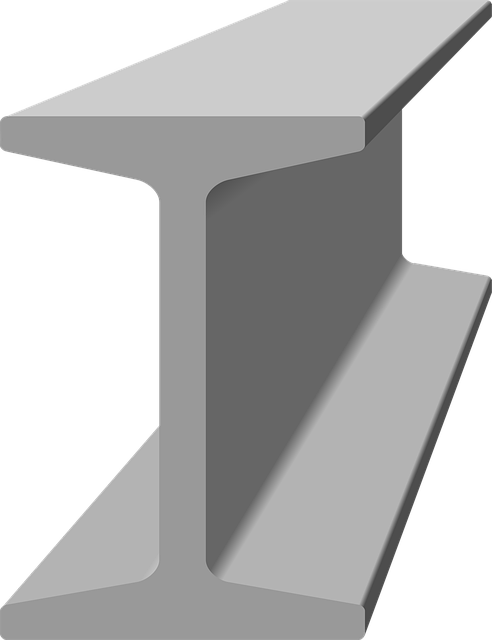

In the realm of construction and engineering, the seamless integration of structural components is paramount for robust and durable buildings. Among these components, glue laminated beams stand out as a critical element in modern architecture, offering unparalleled strength and versatility. This article delves into the world of “Where to Buy Glue Laminated Beams,” exploring its definition, global impact, economic implications, technological advancements, regulatory landscape, challenges, successful case studies, and future prospects. By the end, readers will grasp the significance of this construction technique and the strategic considerations involved in sourcing these specialized beams.

Glue laminated beams, also known as GLB or glue-laminated timber, are engineered structural elements created by laminating multiple layers of wood veneers with strong adhesives. This process enhances the natural strength and stiffness of wood, making it an innovative solution for building construction. The core components include:

The concept of glue laminating wood dates back to the early 20th century, with significant advancements made during World War II when material shortages prompted the development of engineered timber products. Today, GLB is widely recognized for its:

The use of glue laminated beams has spread globally, driven by the increasing demand for sustainable, high-performance building materials. Key regions leading in GLB adoption include Europe, North America, and Asia-Pacific:

Several global trends are influencing the market for glue laminated beams:

The global glue laminated beams market is characterized by:

GLB plays a vital role in economic systems by:

Technological advancements have revolutionized the manufacturing process of glue laminated beams:

These innovations have led to:

Emerging technologies like:

The regulatory environment surrounding glue laminated beams varies across jurisdictions but generally includes:

Policies and regulations:

Despite its numerous advantages, glue laminated beams face several challenges:

Strategies to address these issues include:

This iconic skyscraper showcases the use of glue laminated beams in high-rise construction. Over 7,000 GLB components were utilized for its structural framework, contributing to its remarkable height and architectural splendor. The project’s success highlights the ability of GLB to support extreme loads while maintaining aesthetic appeal.

A groundbreaking sustainable bridge project in London employed GLB for its deck system. By using locally sourced timber and advanced engineering, the bridge offers a lightweight, durable structure with reduced environmental impact. This case study demonstrates GLB’s role in promoting eco-friendly infrastructure development.

The expansion of Oslo’s metro system incorporated GLB for its underground stations’ structural support. The material’s strength and compact size facilitated efficient construction, ensuring the project stayed on schedule and within budget. This application highlights GLB’s versatility in challenging urban environments.

To capitalize on future prospects:

“Where to Buy Glue Laminated Beams” is a dynamic and evolving landscape, shaped by technological advancements, global trends, and sustainability imperatives. As the construction industry seeks innovative, high-performance materials, glue laminated beams stand out as a game-changer, offering superior strength, durability, and environmental benefits. By understanding its history, economic implications, technological advancements, and regulatory frameworks, stakeholders can navigate this complex yet promising domain.

Q: Are glue laminated beams more expensive than traditional wood?

A: While the initial cost may be higher, GLB’s long-term durability and strength often lead to cost savings in construction projects.

Q: How do I choose the right adhesive for GLB production?

A: Adhesive selection depends on factors like desired strength, environmental conditions, and specific wood types. Consulting with adhesives specialists is recommended.

Q: Can glue laminated beams be used for outdoor applications?

A: Yes, certain GLB products are treated for enhanced resistance to moisture, pests, and weather, making them suitable for exterior construction.

Q: Are there any health risks associated with working with GLB?

A: When handled properly, GLB poses minimal health risks. However, standard safety protocols, such as wearing protective gear, should be followed during processing and installation.

Q: How do I ensure the quality of glue laminated beams for my project?

A: Quality control measures include testing for strength, dimensional stability, and adherence to relevant building codes and standards. Reputable manufacturers maintain rigorous quality assurance processes.

Reclaimed Glulam beams (Glue-Laminated Timber) are available through diverse channels like unalam.com for online purchases, local lumber yards, and co…….

When looking for Where to Buy Glue Laminated Beams, options include local lumber yards, online retailers, specialized suppliers, wholesale co-ops, and…….

When looking for high-quality glue-laminated beams (GLB), explore top online marketplaces like unalam.com for extensive selection and expert advice. A…….

This text introduces Glue Laminated Beams (GLB) as strong, stable structural elements made from gluing wood pieces. It guides readers on buying GLB th…….

Online platforms like [Brand/NAP] and specialized retailers offer a wide range of glue laminated beams (GLBs) for construction. Key considerations inc…….

When buying Glue Laminated Beams (GLBs) for construction, prioritize material quality from reputable suppliers. Compare prices, brands, and reviews on…….

Purchase high-quality Glue Laminated Beams (GLB) from reputable online stores like [brand/website] or local suppliers for competitive pricing and sele…….

Glue laminated beams (GLBs) offer superior strength and stability for construction. Purchase from local suppliers, hardware stores, online marketplace…….

Understanding glulam pricing dynamics is crucial when sourcing glue-laminated beams. Prices vary by wood type, laminating complexity, supplier locatio…….

To find the best deals on Glue Laminated Beams (GLULAM), compare prices from various retailers including online marketplaces, local lumber yards, hard…….